3D printing by

Metal Additive Manufacturing

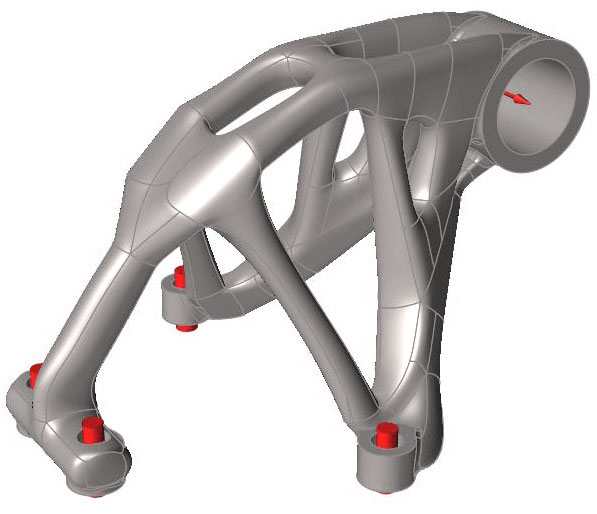

Intended for high technology sectors and complex parts they have their most current bet, the additive manufacture in metal 3D printing.

VEROT | Additive Manufacturing and 3D Technologies

R&D&I

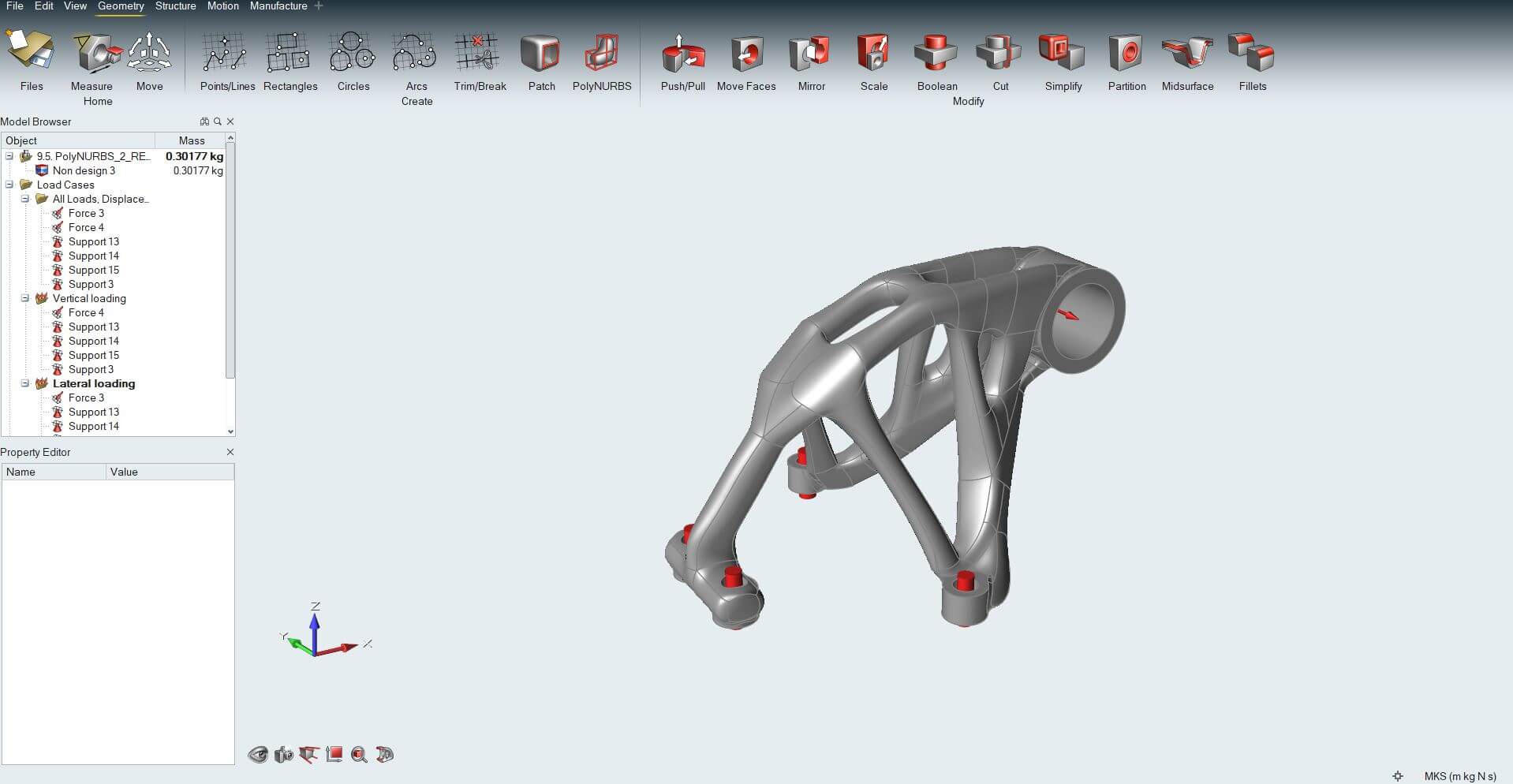

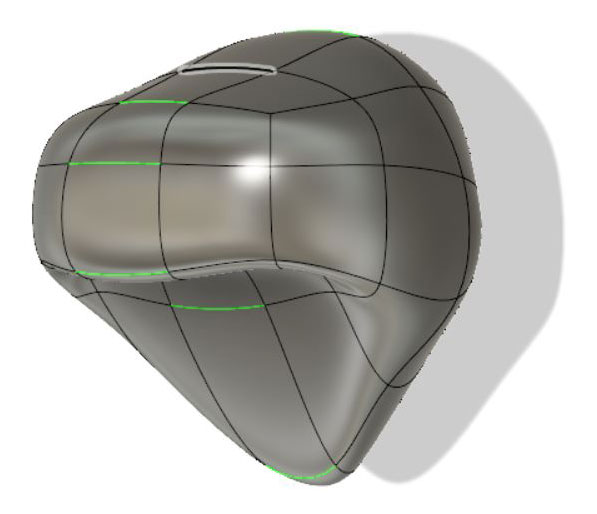

Our engineering department guides you throughout the process, improving the design in order to reduce costs and offer new solutions to deliver a product that is technologically more advanced. We do Reverse Engineering, Generative Design and Topological Optimization. We do Reverse Engineering, Generative Design and Topological Optimization.

Additive Manufacturing

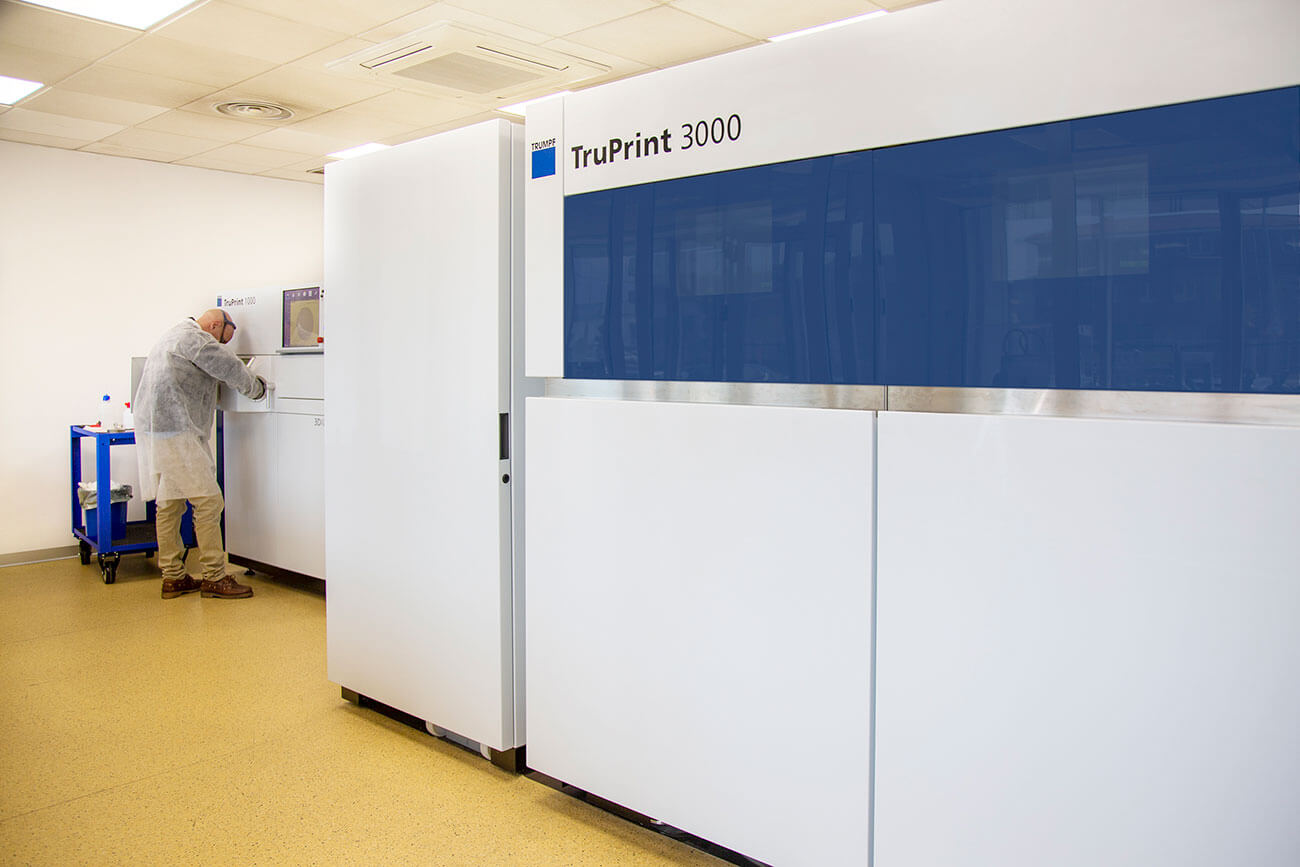

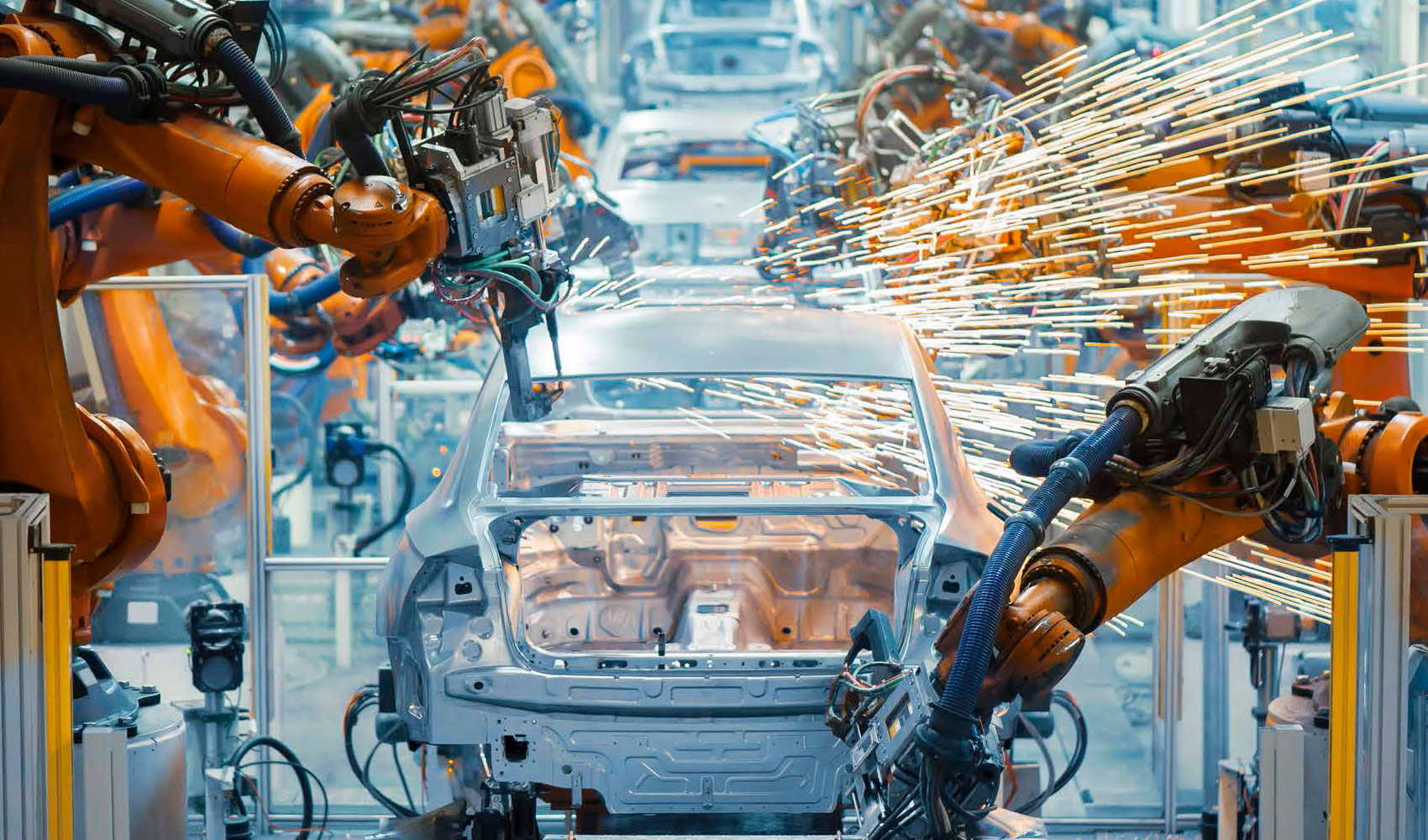

VEROT, S.A. offers metal transformation services and 3D printing by metal additive manufacturing. VEROT, S.A. uses leading manufacturers machinery in 2D, 3D laser cutting and laser tube, water jet cutting, plasma, folding, punching and welding (robotic, laser and manual). They are also a reference in metal transformation and the development / manufacturing of specific transport racks.

VEROT, S.A. provides part for high technology sectors such as renewable energy, biomedical, automobile, machinery manufacturing, nuclear, railway, aerospace, agricultural and defense-military sectors.

WORKSHOP MACHINERY

layer height 30-100 microns.

layer height 20-60 microns.

Thermal treatment furnace with controlled

atmosphere – Up to 1.300º C

Dimensions Ø 300 x 400 mm.

Blasting unit 500 x 400 mm – Glass micro beads,

corundum, etc.

Sieves (2) – up to Ø 1 meter

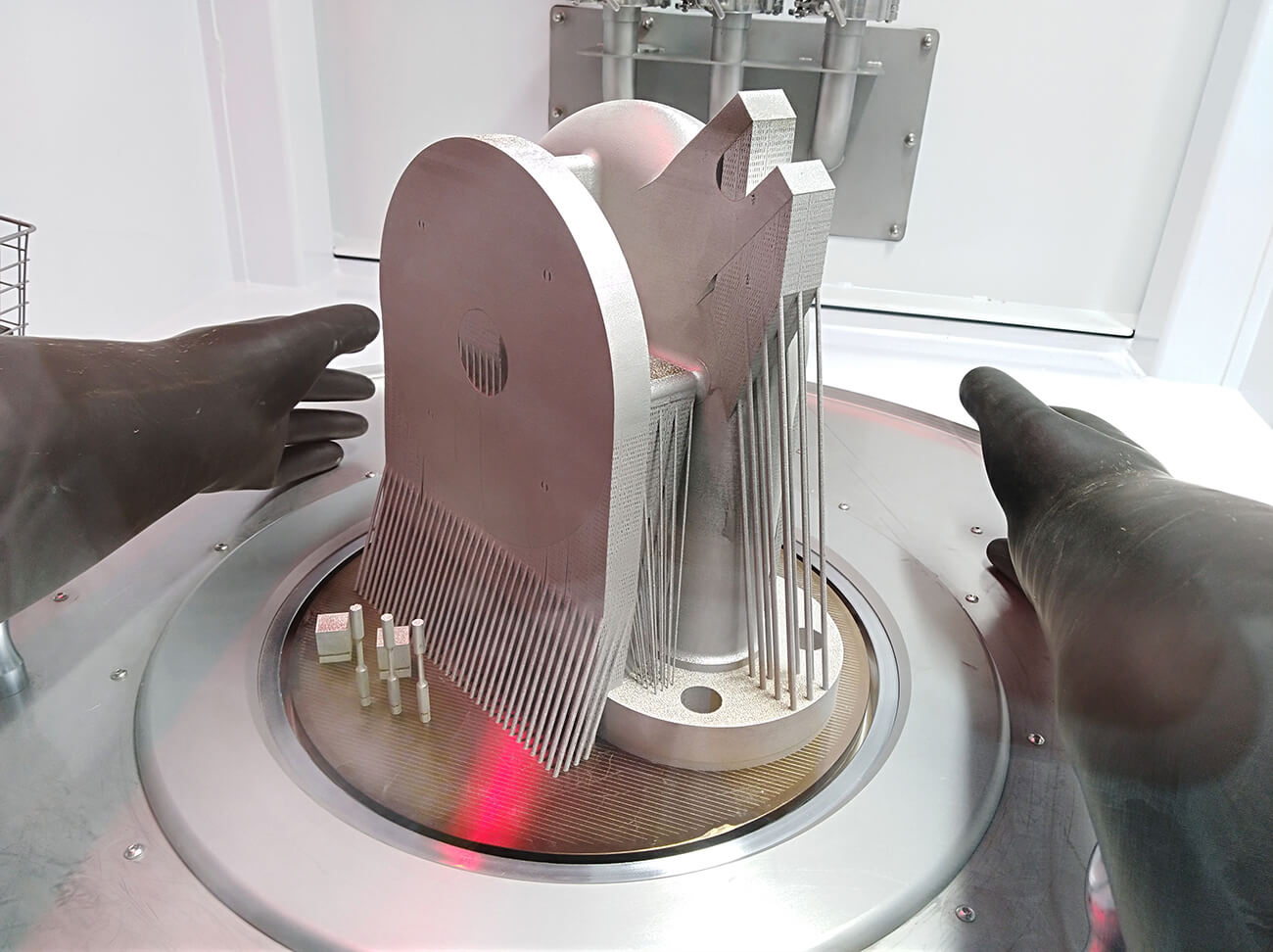

Glovebox, with controlled atmosphere.

Ultrasonic bath

- Stainless steels AISI 316L, 17 4 PH

- Tool Steel

- Titanium

- Inconel

- Cobalt chromium

- Aluminium

Addadvantages Additive Manufacturing

Printing

We print with a wide range of materials without using different machines.

Components

We design complex components without additional costs

Costs

No moulds

No moulds, no need to invest in manufacturing tools.

Speed

You can constantly review and update the designs. Speeding up the time lines to place products on the market.

Risk free

No risks or costs associated to the maintenance of stocks.

Automotive

Health

Aeroespace

Industrial

Our is a Global Market

We are located in Asturias (Spain)

and work with clients all around the world